This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Ask us for a quotation

We are proud to offer you the TractionElite MR and MRL! Hydroware’s highly appreciated solutions are now available not only for hydraulic lifts, but also for traction lifts. We are opening up to send you a quotation with our TractionElite MR and MRL. Please use the quotation and offer form for TractionElite when asking for a quotation. Using the form will speed up the process, giving us all the information we need to send you a complete quotation. When everything is filled out correctly, please send the form to sales@hydroware.co.uk

Quotation and order form TractionElite

Send and email to sales@hydroware.se for a quotation or to place your order.

Quick facts about TractionElite MR & MRL

Simple installation

- CANopen Lift technology

- No floor zone sensors needed

- No limit switches needed

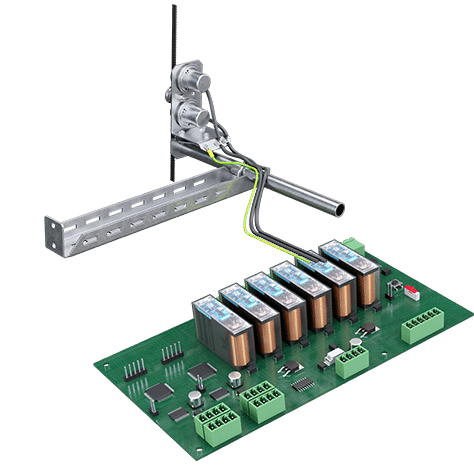

- Innovative pit box

- Automated test procedure

- Simple commissioning

- SIL3 certified Position Supervisor Unit

- Decentralized user interface – MRL

10 ” touch display

- Easy to navigate

- Language options

- Instruction movies in display

- Training sessions simplified

- Integrated diagnostic tool

- Real time and historical data

- Safety circuit overview

- Full accountability

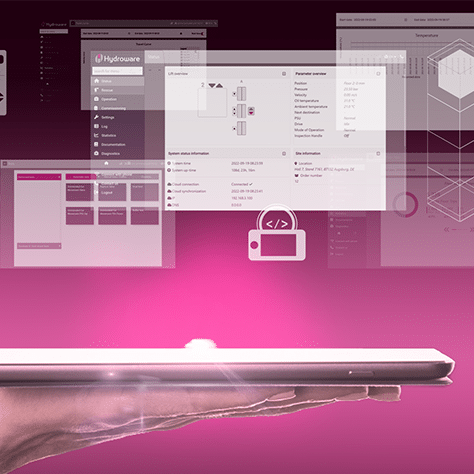

Stay connected – HydroCloud

- HydroCloud connection

- Always updated documentation

- Remote software updates

- Remote monitoring

- Access from anywhere

- Live internal drawings

- Better planning of maintenance

- Constantly evolving IoT

- Local Wi-Fi enables access from smart devices

News – TractionElite

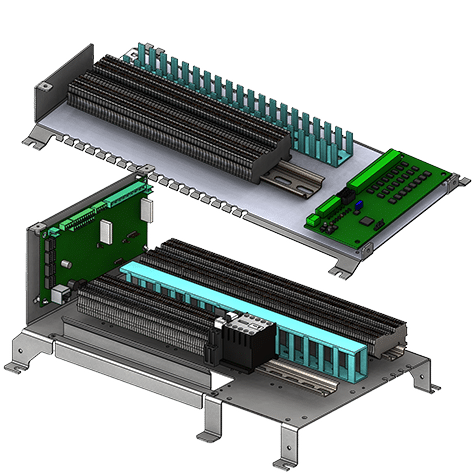

PSU H2 DILIGENS

A safe absolute positioning system with UCM and overspeed tripping functions. Activates electrical safety gears and replaces all safety-relevant limit switches and floor sensors.

- SIL3 compliant and certified according to EN81-20/50 PESSRAL.

Decentraliced user interface

With TractionElite H2 MRLs decentralised user interface, the aesthetic impact will be held to a minimum after a modernisation. The decentralised control box, housing the 10-inch touch display and user interface, is placed on a wall outside of the shaft and measures approximately 30×50 cm. The larger control box, including the frequency converter, is placed inside the shaft.

10-inch touch display and accessibility

The control unit is fitted with a 10-inch high resolution touch display. Among other features, the user will be able to find documentation, schematics, historical data and error logs directly in the display. Furthermore, there are instruction movies and language options available. The lift controller is accessible from any smart device and enables the user to connect to the controller from anywhere in the lift shaft.

Surveillance, access and updates with cloud connection

All units come with HydroCloud readiness. Thanks to the HydroCloud connection, the unit can be accessed from anywhere. The unit can be updated remotely, allowing documentation to be up to date to the latest version. The system is open and can be adapted to work with other monitoring systems on the market.

Pit and car node

Our new innovative pit node is installed in the shaft pit and is designed to cut down the amount of wires that run from the lift shaft to the motor room. Similarly, the updated car node is smaller and better prepared for a quick and neat installation. Due to even more wires being pre-wired with plugs, the on-site wiring is very fast and basically Plug and Play.

Different models of TractionElite and HydroElite drive and control systems

TractionElite is available in MR and MRL configurations.

HydroElite is available as H2 and V5 – VENI, VIDI, MINI and MRL.